PROCESS OF JOINING / INSTALLATION

Polythene or Polyethylene sheets are commonly used as a damp-proof membrane in construction sites, for all but severe conditions of dampness.

Where site conditions are reasonably dry and clean, the overlap joints between the sheets are sealed with mastic or mastic tape between the overlapping sheets and completed with a polythene joining tape.For this lapped joint to be successful the sheets must be dry and clean, else the jointing tape will not adhere to the surface of the sheets. As clean and dry conditions on a building site are rare, this type of joint should be only used where it is unlikely to have heavy absorption of ground moisture.

Where site conditions are too wet to use mastic tape, the joint is made by the overlapping sheets with a double welding fold. This fold is kept in place by weighing it down with bricks or securing it with tape. The double weld is formed by folding the edges of sheets together and then making a welding which is flattened.

The plastic sheet is effectively impossible to fold because of its stiffness and elasticity.It always tends to unfold so it requires a deal of patience to fold, hold in place & then contrive to fold along the joint. By using the maximum size of sheet available it is possible to minimise the number of joints.

At the internal angle of walls, a cut is made in the sheet to facilitate making an overlap of sheet at corners.These sheets which are commonly used as a damp-proof membrane will serve as an effective barrier to rising damp,provided they are not punctured or displaced during subsequent building operations.

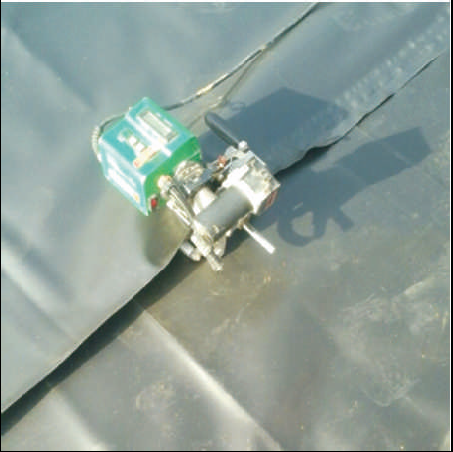

We use Automatic Sealing/Combi-wedge welding machines with step-less adjustable temperature and drive manufactured by M/s Leister Technologies, Switzerland, as also hand sealing machines for welding joints and cross overlaps. The above state of the art hot air blow sealing machine weighs approx. 6.5 kgs and operates on a voltage of 220-230 volts.The temperature of the machine is digitally controlled with a max. heating up to 600 deg.C.

The salient features of the machine are as follows:

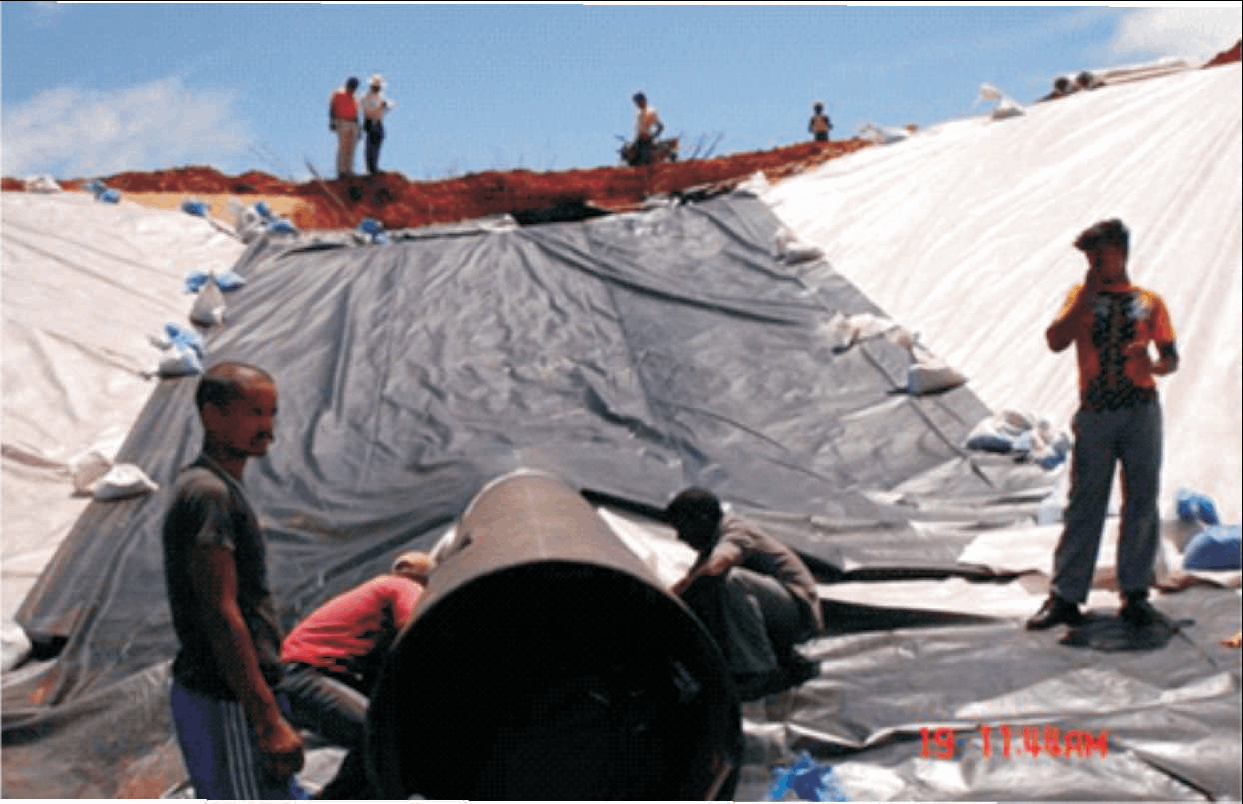

METHODOLOGY FOR SEEPAGE BARRIER LINING

Scope

This specification covers supply, laying,welding, repairing and protection of under slab seepage barrier lining for preventing the penetration through the slab of damaging alkaline salts, moisture, mold, radon gas and water seepage.

Surface Preparation

Material

- Seepage Barrier lines of thickness of 0.25mm -1.5mm for the area of coverage

- Seepage liner should be smooth, uniform in colour, texture & finish, free from pin holes, un dispersed raw material, streaks & particles of foreign matter, no other visible defects uch as melt fracture, holes, tears or blisters dry.

Installation

- Unroll the Seepage barrier sheet above well prepared surface with the longest dimension parallel with the direction of the po

- Mark 100 mm overlaps over the edges of liner (length and widthwise) by drawing a white line using a marker pencil

- Adjacent layers shall be laid within 100 mm overlap

- The overlaps shall be cleaned to ensure free from dirt and moisture

- Overlaps are welded with Leister automatic/ hand held hot air fusion welding machine with correct temperature, pressure and speed

Terminations