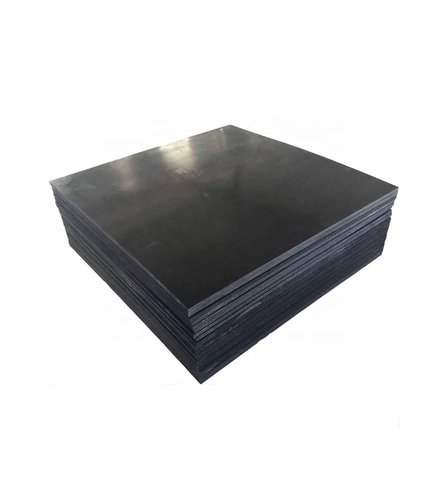

High-Density Polyethylene (HDPE) sheet is made of High-density polyethene plastic and is most commonly known and referred to as HDPE plastic sheet. The amount of friction on it is extremely low. Additionally, the HDPE plastic sheet is extremely impact and abrasion resistant. Along with being moisture, stain, and odor-resistant, the HDPE plastic sheet is also FDA approved. This thermoplastic is made from a string of ethylene molecules (hence, the poly part of polyethene) and is known for being both lightweight and strong. The demand for HDPE sheets has increased as more businesses adopt sustainability initiatives because of how little HDPE Membrane is needed to produce and package products thanks to the sheet's strength and weight.

There are many reasons why HDPE sheeting is popular, and depending on who you ask, you may get a variety of answers as to what the main advantage is. The following are the main advantages of HDPE sheets:

1. Weight: As previously mentioned, HDPE is renowned for being incredibly light while still being strong.

2. Malleability: HDPE is flexible enough to be molded into almost any shape or pattern.

3. Resistance: HDPE Sheet has a high level of chemical and impact resistance. Additionally, the most interesting fact about them is that they are also resistant to rotting, insects, mildew, and mold.

4. Weather resistance: HDPE sheet is frequently used outdoors because it can withstand even the worst weather conditions.

5. Lifespan: HDPE outlasts conventional HDPE Membrane due to its high impact, chemical, and weather resistance.

6. Durability: As was already mentioned, one of the factors that contributes to HDPE's popularity is its durability while still being lightweight. If you have ever dropped a child's plastic toy, you have probably seen how durable HDPE is because it does not break but instead "bounces" back.

7. Sustainability: HDPE sheeting is recyclable, which is why many recycled plastic products, such as recycled plastic lumber and trash, can contain HDPE.

These and other advantages, such as advantages specific to applications, all help make plastic a successful and well-liked HDPE Membrane.

What are HDPE Sheets Used For?

Given that you are aware of its biodegradability, are there any additional applications for HDPE film? Well, HDPE film is occasionally blended with LDPE to change its properties, in addition to having many of the same uses as LDPE and LLDPE film. HDPE is best used in applications that call for increased tensile and compression strength as well as improved stiffness and rigidity. HDPE has superior impact strength and corrosion resistance, just like LDPE.

Due to their low odor, high chemical resistance, and inertness, many PE grades are permitted for packaging applications under FDA guidelines. Due to the high boiling point, several grades can be sterilized in boiling water. Bags, liners, agricultural and construction films, as well as food and nonfood packaging, are common applications for HDPE film.

Due to its down-gauging properties, which enable thinner films and packaging (i.e., less HDPE Membrane is used) while still delivering an equivalent level of performance, HDPE has dominated the market in recent years. HDPE films typically range in thickness from 0.0005 to 0.030 inches. They are available in opaque and translucent hues. There are also UV, flame-retardant, and anti-static additives for HDPE.

Common Applications of HDPE Sheets

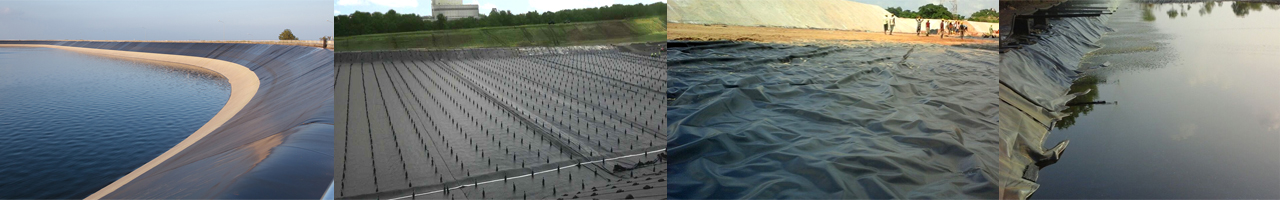

HDPE sheets are now preferred for many projects, including those that are residential, commercial, industrial, and maritime. HDPE sheets Manufacturer are well-known for their dependability in all weather conditions and durability in residential applications. Outdoor furniture, outdoor kitchens, playgrounds, bathroom partitions, site furnishings and amenities, and landscape architecture are just a few uses for HDPE sheets.

Additionally, in commercial, industrial, and marine applications, HDPE sheets perform better than conventional wood. HDPE performs well as a building HDPE Membrane for marine decking. Similar in appearance to real wood, HDPE marine decking requires less maintenance and waterproofing while offering excellent environmental resilience. The wood grain finish maintains a natural wood appearance while adding to the slip-proof resistance. Commercial marinas and docks benefit from using HDPE sheets due to these advantages.

In even more applications, high-density polyethylene is superior to other HDPE Membrane. Golf courses, parks, recreation centers, and other amenities found in commercial and urban sites frequently use HDPE. It can also be used for hospitality, outdoor living, and specialty business solutions. Due to the versatility of high-density polyethylene HDPE Membrane, commercial properties that want to enhance their current aesthetics or functionality have more style and performance options.

Types of HDPE Sheet

High density polyethylene plastics come in a variety of forms, each with a unique use or application.

1. HDPE Smooth Sheet

Smooth HDPE sheeting is the perfect HDPE Membrane for many applications due to its many beneficial characteristics. It is simple to fabricate smooth HDPE, which also has good chemical resistance, tensile strength, and impact and moisture resistance. Tank lining is one of the most popular uses for HDPE smooth sheeting.

2. HDPE Pipe Grade

When compared to HDPE sheeting, pipe grade HDPE plastic performs better and weighs less. The most widely used HDPE sheet for outdoor applications is pipe grade HDPE due to its improved features.

3. HDPE ColorCore

In order to create signs and letters that reveal the interior color, HDPE Sheets Manufacturer can use HDPE ColorCore, which has a colored HDPE sheet core. The strength and durability characteristics of colored HDPE sheet are identical to those of smooth and HDPE.

4. HDPE Antiskid

Specifically for marine applications where a non-slip or skid surface is required, Antiskid HDPE sheet was developed.

All grades of HDPE plastic sheeting share the same basic traits and benefits that set them apart from other plastic sheeting HDPE Membrane like polycarbonate or acrylic sheet.

Product specifications:

Minimum Order Quantity: 1000 Kilograms

Material : HDPE Membrane

Thickness: 250 microns - 1.5 mm

Sizes: Up to 6 Meter

Additional Info:

- Pay Mode Terms: NEFT/RTGS/Cheque

- Delivery Time: 5-7 Days

- Port of Dispatch: Delhi & Haryana

- Production Capacity: 600 Tons Monthly